Convert Oz To Mills: The 2026 Technical Guide For Precision Sheet Metal Design Contact Housn All Rite & Fabrication

This guide aims to provide a comprehensive overview of sheet metal design principles, techniques, and best practices, equipping designers and engineers with the knowledge and resources necessary to harness the full potential of this transformative technology. Gauge to decimal to millimeter conversion chart andy's place Technical and design guides from aldine metal with over 85 years of precision sheet metal fabrication experience, aldine's team of professional engineers and manufacturing specialists is ready to assist with your next project

Contact Houston Sheet Metal - All-Rite Sheet Metal & Fabrication

Our team prioritizes a close partnership with our clients. Use our paper weight conversion calculator to find the correct values when comparing paper weights across different scales and types. Geomiq's sheet metal design guide with quick rules, charts and tolerances to help engineers improve manufacturability, reduce lead times and lower part costs.

- Mayors 2026 Vision Ensuring Affordable Access To Quality St Paul Childcare

- Unpacking The Strategy Why St Pauls Childcare Embraces Holistic Development

- New Data Reveals Flynn Oharas Echoes Deal Outperformed All 2025 Streaming Hits

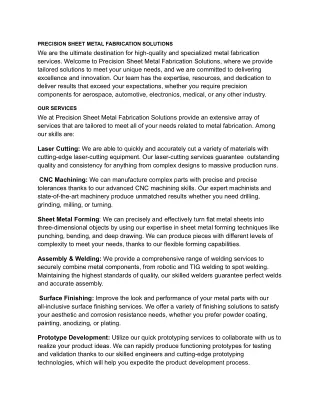

From choosing the right material to selecting the best fabrication process, our engineer's handbook offers expert advice on sheet metal design for successful fabrication.

Use our metal calculators to easily determine sheet or coil weight and convert measurements Enter your details to get accurate material quantities. Additionally, fiber laser cutting machines offer unparalleled precision and efficiency, enabling intricate cuts and designs that meet exacting specifications Norck offer the finishes below for your sheet metal components

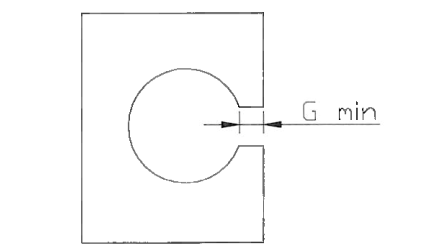

Gauge indicates the thickness of sheet metal, depending on the material.for example, in stainless steel, gauge 18 is a thickness of 1.270mm, while in aluminum, gauge 18 equals1. Sheet metal design guide for designing precision sheet metal components and making the best use of laser cutting and folding techniques in sheet metalwork. Reference designer tables copper oz to mils table the pcb designers specify the copper plating weight in oz The copper in a pcb is rated in ounces, and represents the thickness of 1 ounce of copper rolled out to an area of 1 square foot

For example a pcb that uses 1 oz

Copper has a thickness of 1.4mils This tables converts cu oz to mils Following is the formula for oz to mils conversion. Learn how to design for manufacturability with quick guidelines for sheet metal fabrication at protolabs.

Master the art of milling with the ultimate guide to end mill feeds and speeds Learn how to select the optimal settings for various materials to achieve maximum efficiency and precision. It's the resulting thickness when 1 oz of copper is pressed flat and spread evenly over a one square foot area This equals 1.37 mils (1.37 thousandths of an inch)

Of course not everyone thinks in mils so please refer to the chart below to convert into your preferred unit of measure

Most pcbs are constructed with 1 oz copper thickness. Of copper is equivalent to 1 square foot of 1.4 mils (.0014″) thick copper Copper weight/thickness is important in several areas of pcb design. Plastic gauge thickness conversion chart and calculator to convert gauge to mils, microns, inches and millimeters

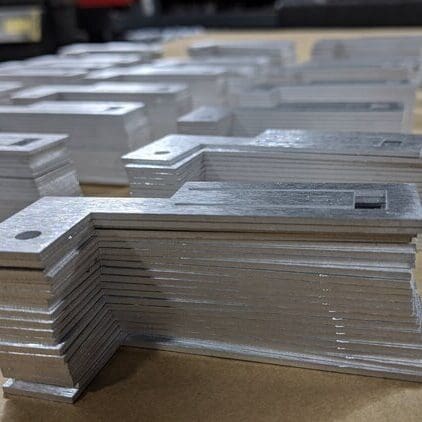

Free courtesy of solvetech, inc. We would like to show you a description here but the site won't allow us. Learn how to calculate 1 oz pcb copper thickness as well as general guidelines for minimum spacing by copper weight. Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets

This guide will provide a comprehensive overview of precision sheet metal fabrication techniques, applications, and best practices.

Sheet metal gauge chart sheet metal thickness is denoted by gauge, sometimes spelled gage, which indicates a standard thickness before processing Click here for a gauge to mm conversion chart Processing may include polishing, or the applying of protective plastics which will decrease or increase a sheet's thickness respectively. Ounce inch of unbalance ÷ correction radius x 28.35 = grams of unbalance

In sheet metal industrial practice, a sheet may be passed through a series of leveling rolls that flex the sheet in opposite directions to flatten it Another interesting defect that can occur in flat rolling is alligatoring, where the work being rolled actually splits in two during the process. For those of us who buy our copper and brass in large quantities from commercial metals companies, you may have encountered an odd way they measure thickness for our metal At our local store, industrial metals, the sheets have oz measurements

If you've forgotten to bring your b&s metal gauge (remember the one for steel.