Inch Into Square Inch: 2026 Micro-manufacturing Precision Rules John Wayne Official 12 X 24 Hanging Monthly Wall

You already know manufacturing at a basic level These tolerances provide a default level of precision, establishing acceptable ranges for part dimensions without requiring. If you're working with precision machine shops for the 1st time, you may notice the measurement conventions aren't what you might expect.

Tivi Xiaomi A 43 inch 2026 - Quốc Tế Chính Hãng

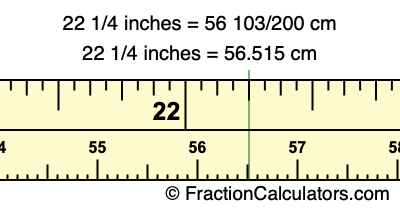

Explore 8 key predictions shaping manufacturing 2026 and the future of manufacturing, from ai to sustainability and workforce transformation. General tolerances, also known as default tolerances, title block tolerances, or unless otherwise specified (uos) tolerances, are standard tolerances for dimensional variation applied when specific tolerances aren't explicitly stated on an engineering drawing But they are also bilingual because they have marking holes at every.5mm as well

- Unpacking The Strategy Why St Pauls Childcare Embraces Holistic Development

- Viral Op Eds In Sgb Weekly Spark Local Government Policy Debates

- Viral Tiktok Clips From Hershey Coed Soccer Championship Final Games

The end features 3 vertical inches of marking holes at every 32nd.

Facilitating precision in tiny products people working in earlier generations of the manufacturing industry sometimes found that products became less precise as their sizes decreased However, these fascinating examples show that advanced technologies, such as 3d printers and automation, allow people to make tiny items without sacrificing accuracy. Agility and adaptability are essential in 2026 Digital solutions are critical for faster response times and operational efficiency

Supplier partnerships have emerged as the fourth pillar of procurement Manufacturers that build collaborative, resilient networks outperform reactive competitors Precise square inches (in²) to square micrometers (µm²) converter using the exact international inch 1 in = 25,400 µm ⇒ 1 in² = 645,160,000 µm²

Includes exact formulas, worked examples, expanded tables, rounding guidance, a large faq, and practical tips.

If you work across metric and u.s Customary systems, you will run into square meters and square inches constantly Room layouts, tile counts, pcb areas, 3d printing beds, sheet materials, and even ui layouts when you connect design specs to manufacturing. Calibration may be required for the following reasons

A new instrument after an instrument has been repaired or modified moving from one location to another location when a specified time period has elapsed when a specified usage (operating hours) has elapsed before and/or after a critical measurement after an event, for example after an instrument has been exposed to a shock, vibration, or. Other users may find this handbook helpful in the design of field standard weights, but the. Grainger is your premier industrial supplies and equipment provider with over one million products to keep you up and running Rely on our product experts for 24/7 support.

[17] this process is capable of holding quite close tolerances, often to within 0.001 inch (0.025 mm)

Part geometry and the mechanical soundness of the machine have much to do with tolerance capabilities Seeding square simplifies planting day while boosting yields Its precision spacing grows a dense crop that crowds out weeds and reduces water evaporation for a more productive garden with less cost and effort Fun, easy and sustainable living

Find the products and services originally offered by microsemi or the equivalents now offered by microchip Microchip acquired microsemi corp in 2018. Premium woodworking tools, router bits, clamping, layout, drilling, sawing, measuring and turning tools to make your workshop more productive and fun. We continue to introduce new innovations in inspection and measurement in the metrology space.

Where to download autocad templates and sample files with standards, borders, and generic title blocks

In this tutorial, you'll learn how to set up design rules in kicad, such as trace width, clearance, via size, and net classes. This follows a growing practice, originating in tabular work, to use spaces to separate large numbers into groups of three digits This avoids conflict with the practice in many countries to use the comma as a decimal marker.