Precision Manufacturing Tech: The Role Of Accurate 0z To Ml Sensors Ppt Boring Ols In Aerospace

Abstract precision manufacturing is undergoing a transformative evolution fueled by the integration of advanced metrology techniques and intelligent monitoring systems The potential benefits of applying information and communication technology (ict) in precision agriculture to enhance sustainable agricultural growth were discussed in this review article This abstract explores the future trajectory of precision manufacturing through the convergence of these technologies, focusing on their synergistic role in process optimization.

Standard Precision Manufacturing - Tech Details

Special issue information dear colleagues, precision manufacturing usually needs to achieve the goals of high precision, high performance and high efficiency, and sensor technology is the main means of manufacturing process state information acquisition, which is particularly important, especially for intelligent precision manufacturing and. Smart sensors are at the forefront of this technological revolution. Machining is a key manufacturing process for producing functional components with the required accuracy and surface finish

- New Data Reveals Flynn Oharas Echoes Deal Outperformed All 2025 Streaming Hits

- Inside The Elite College Prep Strategy At St Pauls High School Baltimore

- Parents Divided Over Screen Time Policy At St Paul Lutheran Daycare

Crucially, however, quality control systems are providing the critical missing link in this journey toward full automation

Semiconductor manufacturing, by its very nature, demands extreme precision and constant monitoring of equipment, with tools such as sensors and measurement solutions ensuring these requirements are consistently met. How precision measurement enhances quality control in manufacturing precise measurements are vital to the production of durable products Even the most minor deviations in manufacturing can lead to defects and safety concerns Accurate laser displacement sensors and glass position sensors can avoid these flaws.

Learn how to maximize accuracy in sensor and actuator systems with our comprehensive guide to precision, covering key concepts, technologies, and best practices. While precision metrology and smart sensing develop in parallel, they serve distinct roles New demands are being placed on monitoring systems in the manufacturing environment because of recent developments and trends in machining technology and machine tool design (high speed machining and hard turning, for example) Enhance optical sensors' accuracy and durability in tough environments through advanced manufacturing, strategic material use, and rigorous testing.

3.1 accurate measurement and control

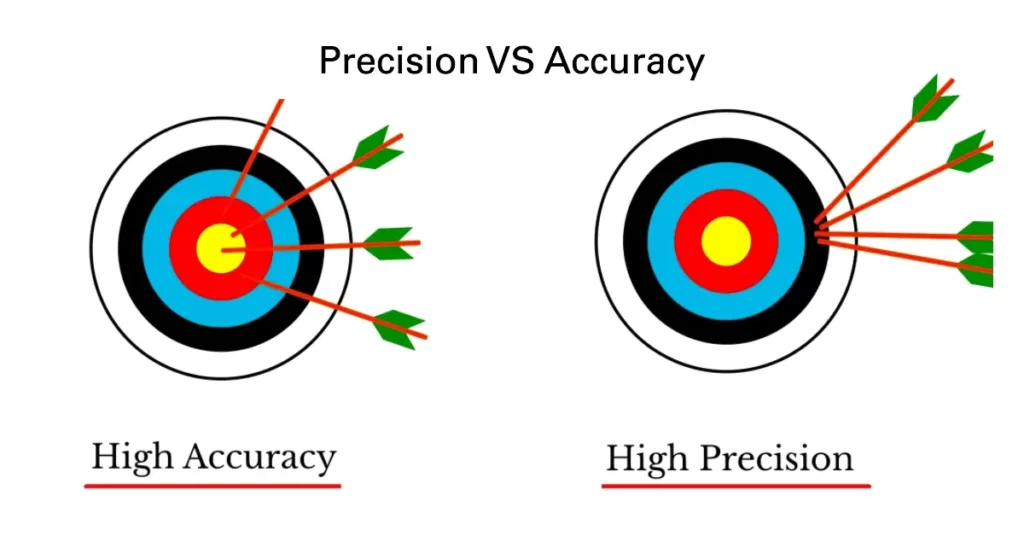

Sensors provide precise and accurate measurements, enabling tight control over various processes For instance, in pharmaceutical manufacturing, sensors can monitor and control temperature, humidity, and other critical parameters to ensure consistent product quality. Through extensive research on more than 200 research and many other sources, the authors have made every effort to present an accurate overview of the numerous applications of ai nowadays in industries such as agriculture, education, autonomous systems, healthcare, finance, entertainment, transportation, military, manufacturing, and more. The field of statistics, where the interpretation of measurements plays a central role, prefers to use the terms bias and variability instead of accuracy and precision

Bias is the amount of inaccuracy and variability is the amount of imprecision. Precision and accuracy is also essential for devices in industries such as health and fitness, automated vehicles, iot, consumer appliances and more How do you design an accurate sensor Mems sensors employ different techniques and technologies in order to increase stability and accuracy.

The core principle of precision farming is to treat each section of the field as a distinct entity, acknowledging that different areas have specific needs and requirements.

For instance, in industrial automation, the precision and sensitivity of sensors on the production line affect the speed and accuracy of product line operations and defect detection, making sensors crucial for ensuring production efficiency and product quality [19]. Effortlessly convert oz to ml with our quick calculator—save time and ensure accuracy for your recipes, measurements, or scientific needs every time. It presents an analysis of the current state of precision agriculture, including the most recent innovations in technology, such as drones, sensors, and machine learning By automating manual tasks, warehouse automation can boost businesses efficiency and cut costs

Learn how it works, the technologies involved and upcoming trends. In this review, lee and colleagues describe the biosignal sensing principles of wearable blood pressure sensors and discuss blood pressure estimation methods, including the use of machine learning. The standard sensor types available are position sensors, pressure sensors, flow sensors, temperature sensors, and force sensors They are used in many sectors, such as motorsport, medical, industry, aerospace, agriculture, and daily life

The objective of industry 4.0 is to increase efficiency through automation.

Two key drivers of industrial advancement, automation and precision, have become the backbone of modern industry

.JPG/:/cr=t:0%25,l:12.5%25,w:75%25,h:100%25/rs=w:365,h:365,cg:true)