Automated Bottling Systems Will Standardize Every Pour From Oz To Ml Daily Semi Au Wine Line Criveller

Boosting productivity by standardizing every shift in your bottling plant this guide explores how bottling plants can standardize operations across all shifts to maximize productivity, minimize downtime, and ensure consistent product quality. For instance, one beverage manufacturer reported a 30% increase in output after installing an automated filling system, which substantially reduced downtime as. Automated bottling machines come with advanced control systems that allow you to monitor the performance of your production line in real time

Bottling Systems | Lease/Finance Or Buy On KWIPPED

You can collect data on the filling speed, volume, and any issues that may arise, which helps you identify and address potential problems before they cause major disruptions. Successful implementation in beverage industries many companies have already witnessed the transformative effects of integrating automated bottling machines into their production lines The evolution from manual to automated processes, and now to more sustainable and smart technologies, highlights their critical role in meeting industry demands

- Social Media Erupts Over New Saint Pauls School Admissions Policy Is It Fair

- Inside The Sustainable Land Management Techniques Of Branch Kampe

- Viral Family Stories Praise St Pauls House A Lutheran Life Community

The key benefits of modern bottling machines are clear

Increased efficiency, productivity, and a move towards more sustainable practices. Agile manufacturing in bottling, powered by manufacturing process planning and standardized automation, is transforming the industry By implementing these strategies, bottlers can adapt to market demands, improve production efficiency, and maintain consistent quality across all facilities. The internet of things (iot) plays a pivotal role in the evolution of automated bottle filling technology.

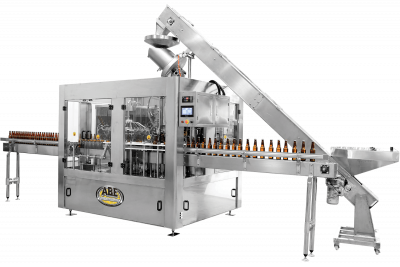

Modern automated bottling production lines consist of various components such as filling machines, capping machines, labeling systems, and conveyor belts that transport products between stages Automation in bottling is transforming production lines across industries, particularly in wine and beverage manufacturing Whether it's still or sparkling wine, an automated bottling system can ensure precision, speed, and quality in every bottle The right automated systems are key to optimizing the bottling process, reducing human error, and increasing overall productivity

A leading developer and manufacturer of complete packaging solutions where bottling systems are an integral component

Accutek packaging equipment companies offer a wide variety of bottling machines, as well as capping, and labeling machines. Sustainability is a driving force in the evolution of automatic water bottling systems, with innovations aimed at reducing environmental impact Automated bottling lines have revolutionized the beverage and food manufacturing industries by streamlining processes, reducing labor costs, and increasing production efficiency These examples illustrate how automation can lead to.

The actual amount of water filled into bottles is normally distributed with an adjustable mean p and standard deviation of 0.2 ounces each bottle has & capacity to hold as much as 26 ounces of water_ 12_ if the machine is adjusted s0 that p = 24 ounces, what percentage of all bottles filled will contain at least the amount of water shown on. However, not all cans will contain the same volume due to variation in the filling process. We're on a journey to advance and democratize artificial intelligence through open source and open science. Professional water bottling equipment and beverage filling lines for startups & enterprises

Reduce costs by 40% with automated bottling solutions.

One critical application is the automated bottling and filling system, where precision and speed are of the essence Study with quizlet and memorize flashcards containing terms like what does x ~ n(µ, σ) mean?, ex (apple juice) The central role of the bottling machine in modern beverage production understanding the bottling machine as the core of automated production lines bottling machines have become essential equipment in beverage production facilities today They handle everything from filling containers to applying caps, labels, and even performing basic quality checks all within one streamlined process