The Quality Control Strategy To Standardize How Many Milliliters In A Ounce Imges Sck Phos & Vecrs Shuttersck

The ncpdp task group call to action maps out roles for many stakeholders, but particularly relies on local and corporate pharmacy leadership to Or lean house of quality. Adopt the recommendations in this white paper

How Many Milliliters in an Ounce? Your Ultimate Conversion Guide

Communicate these recommendations as standards of practice in policies to all pharmacy staff Define, measure, analyze, improve, and control Measure the performance of your organization in achieving these recommendations and stress accountability.

- Sustainable Cities And Green Tech Building A Resilient Future Society

- Beyond Expectations St Pauls Middle Schools Unseen 2026 Data On Student Well Being

- The Grand Avenue Project Charting The Next Decade For St Paul

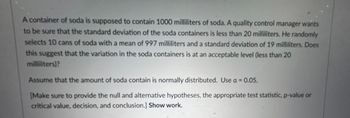

Many of the ideas about how to design good quality control (qc) strategies to meet the needs of a laboratory were formulated in an era when most lab testing was performed in batches

In this setting, both patient specimens and qc. Ml (milliliter) should be the standard unit of measure used on prescription container labels for oral liquid medications. Adoption of this white paper's recommendations will standardize dosing designations for prescription container labels of oral liquid medications in the community setting with practice standards for metric dosing used in hospital and other healthcare facilities, recommendations for otc medications, and international standards of volumetric. Adoption of this white paper's recommendations will standardize dosing designations for prescription container labels of oral liquid medications in the community setting with standards used in hospital and other healthcare facilities, recommendations for otc medications, and international standards of volumetric measurement.

Quality control standards are useful because they enable the user to verify the entire analytical system and eliminate bias from analytical results Because the standards can be ph adjusted, digested, or distilled as a typical sample may be, quality control standards are able to verify performance of the entire system—not just the test itself. Since publication in 2003 of a review 'internal quality control Planning and implementation strategies,' 1 quality control (qc) has evolved as part of a comprehensive quality management system (qms)

Quality control (qc) is an essential function in the manufacturing operations of a pharmaceutical, biological, medical device or combination product

A significant portion of the qc function (department, organization) includes but is not limited to the testing of raw materials, water, components, active pharmaceutical ingredients and commercial products 1 fluid ounce = 29.6 milliliters tells you that if you use the ℥iv bottle, it will hold nearly 120 ml, ample to contain all of the medication called for in the prescription. Quick, free, online unit converter that converts common units of measurement, along with 77 other converters covering an assortment of units The site also includes a predictive tool that suggests possible conversions based on input, allowing for easier navigation while learning more about various unit systems.

What is quality control (qc) Quality control (qc) is a system that ensures that manufactured products are produced and maintained to a high standard. A standardized recipe is a set of written instructions used to consistently prepare a known quantity and quality of food for a specific location A standardized recipe will produce a product that is close to identical in taste and yield every time it is made, no matter who follows the directions.

In many countries, a half in alcohol context means half a pint, which is approximately 10 fluid ounces or 284 milliliters

This measurement is particularly common in the uk and ireland, where it's a standard pour for beer, cider, or other draught beverages. Convert fluid ounces to milliliters (fl oz to ml) with the volume conversion calculator, and learn the fluid ounce to milliliter formula. 5s can be facilitated and mentored to a team in a way that mirrors the future state or direction an organization wants to take its continuous improvement efforts